The product that won the “Japan Power Award” in the “2021 “Super” Component Manufacturing Grand Prix” was the “Circular Groove Integrated Ball Screw for Electric Brake Actuator” developed by NSK Seiko Co., Ltd. (NSK).

The high-response, high-speed rolling screw type contributes to the electrification of automobiles, the field of autonomous driving, and sports damping systems.

The core of the establishment of the Japan Power Award in 2004 is to re-recognize the strength of Japanese manufacturing and to boost Japan’s industry and development. In the six fields of “machinery”, “automotive”, “electrical/electronic equipment”, “environment-related”, “health/social medical care”, and “life-related”, selected and silently produced outstanding products in those fields in Japan Contributed products.

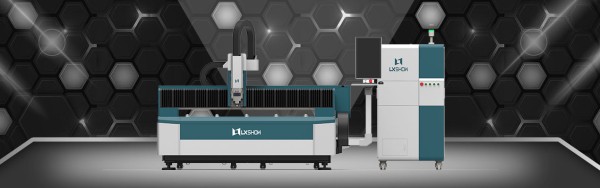

Laser processing technology is the product of modern scientific development. As a new technology, laser cutting, laser cleaning, laser welding, laser marking and other technologies are increasingly used in the sheet metal processing industry.

The sheet metal industry in the fields of machinery, automobiles, and electronic equipment is one of the most important application markets for metal plate fiber laser cutting machine.

In the electrical processing and manufacturing process, the parts processed by sheet metal account for more than 30% of all product parts. Traditional processing techniques (cutting, corner cutting, opening and trimming, etc.) are relatively backward, which affects product quality and increases production costs. Fiber laser cutting machine plate is superior to traditional processing methods in terms of flexibility and processing accuracy. CNC fiber laser cutting machine sheet metal is “non-contact processing”, which does not require molds and reduces production costs. The processing graphics are made by software, with various patterns can bring better production efficiency to manufacturers

Advantages of sheet fiber laser cutting machine

1. Laser cutting has a high degree of automation, fast cutting speed, and short product production cycle. No matter it is simple or complex parts, it can be used for rapid prototyping and cutting by laser;

2. Narrow cutting seam, good cutting quality and easy operation;

3. It can realize cutting and automatic layout and nesting, and the material utilization rate is high;

4. Low production cost and good economic benefit.

Media Contact

Company Name: Jinan Lingxiu Laser

Email: Send Email

Phone: +86 176 8661 2559

Country: China

Website: https://www.lxshowlaser.com/