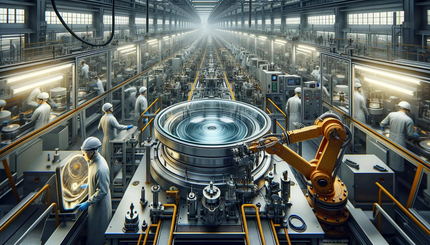

The manufacturing industry stands on the brink of a new era, propelled into the future by the advent of artificial intelligence (AI). This transformation is particularly palpable in the production of Tempered Glass Lids and cookware, where AI’s promise of increased efficiency, quality, and innovation beckons. As we explore the integration of AI into this niche, we uncover a landscape where technology not only augments existing processes but also redefines what is possible.

Bridging Tradition with Technology

The journey of Cookware Glass Lid manufacturing is one steeped in precision and stringent quality standards. Tempered glass lid, known for its strength and safety features, undergoes a thermal treatment process that imbues it with its characteristic resilience. Integrating AI into this process enhances these attributes, bringing a level of precision and efficiency previously unattainable.

AI’s Multifaceted Role

AI’s application in Glass Pan Lids manufacturing is multifaceted, addressing everything from design and production to maintenance and quality control:

1. Quality Assurance: AI technologies, particularly machine learning and computer vision, are revolutionizing quality control in manufacturing. By analyzing real-time data from the production line, these systems identify defects and inconsistencies with unparalleled accuracy, ensuring that every product meets the highest standards.

2. Predictive Maintenance: Downtime in manufacturing can be costly. AI’s predictive maintenance capabilities forecast equipment failures before they occur, allowing for timely repairs and maintenance, thus minimizing disruption and extending the lifespan of manufacturing equipment.

3. Generative Design: In the design phase, AI’s generative design algorithms offer a game-changing advantage. By inputting design objectives and constraints, AI software generates multiple design iterations, optimizing for both function and aesthetics. This not only accelerates the design process but also enables the exploration of complex designs that would be difficult to conceive manually.

Real-World Transformations and Success Stories

The practical applications of AI in this sector are already being realized. Manufacturers leveraging AI for quality control report significant reductions in waste and increased product consistency. Predictive maintenance applications have led to more reliable production schedules, reducing costs associated with unplanned downtime.

For instance, a leading cookware manufacturer implemented AI-driven systems to monitor and adjust the cooling rates during the tempering process, resulting in glass lids that consistently meet stringent safety standards while optimizing the material’s thermal properties for better cooking performance.

Overcoming Obstacles on the Path to AI Integration

The path to AI integration is not without its challenges. The initial cost of adopting AI technologies can be high, and there exists a skills gap in the workforce. Moreover, integrating AI systems with existing manufacturing infrastructure requires a careful approach to ensure compatibility and maximize the benefits of technology.

The Future Horizon: AI and Beyond

Looking ahead, the potential for AI in the tempered glass lid and cookware manufacturing industry is boundless. Advances in AI, especially from leading innovators like OpenAI, promise to introduce new capabilities, from advanced robotic automation that further streamlines production to AI-driven supply chain optimization that ensures materials are used more efficiently and sustainably.

As AI technologies evolve, we can anticipate a future where smart factories not only automate production but also self-optimize in real-time for efficiency and sustainability. The integration of IoT devices will further enhance this, providing a wealth of data that AI can use to make real-time adjustments and improvements.

Navigating the Future

The tempered glass lid and cookware manufacturing industry’s future is inextricably linked to AI. This technology offers the promise of transforming every aspect of manufacturing, from the initial design phase to the final product inspection. As the industry continues to embrace AI, it will unlock new levels of productivity, innovation, and sustainability, ensuring it remains competitive in a rapidly evolving marketplace.

The integration of AI within this industry exemplifies a broader trend across manufacturing sectors, where technology is not merely an add-on but a fundamental driver of change. As we move forward, the synergy between human ingenuity and artificial intelligence will continue to shape the future of manufacturing, heralding a new era of efficiency, quality, and innovation.

Media Contact

Company Name: Ningbo Berrific Manufacture and Trading Co., Ltd.

Email: Send Email

Phone: +8615088417975

Address:No.98-1, District 3, Wanxing Hill, Meiyuan Village, Linshan Town

City: Ningbo

Country: China

Website: https://www.berrificcn.com/