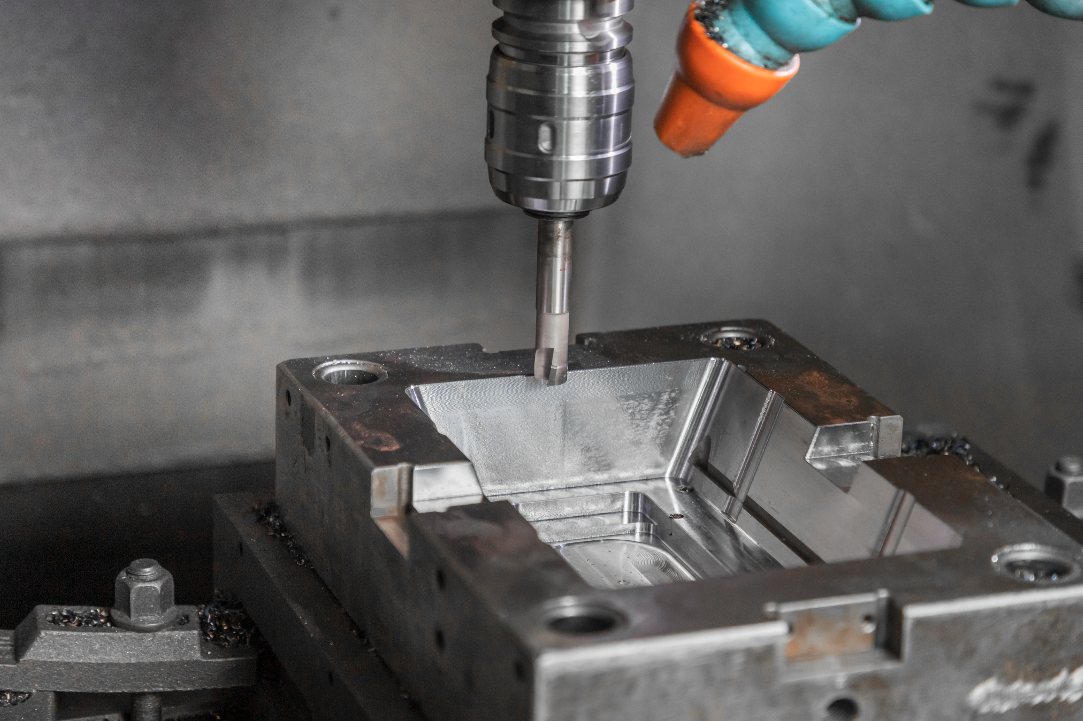

Shenzhen, China – ACO Mold, a premier injection mold and molding manufacturer established in 2000, announces its continued commitment to excellence and innovation in the mold making industry from its 2,000 square meter facility in Shenzhen, China. Equipped with five specialized engineering teams, including project engineers, mold design, CNC machining, QC, and mold manufacturing, ACO Mold offers professional and reliable mold manufacturing and injection molding services. Catering to a diverse client base across various industries such as consumer electronics, home appliances, automotive, medical, and agriculture, ACO Mold has distinguished itself by delivering custom injection molds and molded parts to over 20 countries worldwide. This dedication not only showcases ACO Mold’s prowess in adapting to the evolving demands of global markets but also reinforces its role in driving innovation and quality within the manufacturing sector.

20+ Years of Manufacturing Excellence

ACO Mold distinguishes itself through its remarkable combination of vast experience and expansive facility operations, offering clients unmatched price advantages and flexibility. With an open policy of no minimum order quantity, ACO Mold supports businesses with a holistic custom mold manufacturing solution. This one-stop-shop approach covers everything from mold design and production to injection molding and a myriad of secondary processes, including logo application, spray painting, and achieving pristine high-gloss product finishes. Anchored by over two decades of dedicated service in the mold making and injection molding industry, ACO Mold has evolved into a trusted partner for clients worldwide. This deep-seated experience underlines the company’s ability to deliver not just in terms of cost-effectiveness but also in fostering innovation and quality across various sectors.

Rigorous Quality Control: The ACO Mold Assurance

ACO Mold prioritizes quality above all, implementing a rigorous quality control process that sets the standard in the mold manufacturing industry. From the outset, material quality is strictly monitored, utilizing only client-approved materials sourced from verified suppliers. This ensures that every component meets the highest standards of quality and reliability. In collaboration with clients, ACO Mold establishes and strictly adheres to quality acceptance criteria, ensuring that every product not only meets but often exceeds client expectations.

The company’s dedication to quality extends throughout the manufacturing process, with trained quality auditors meticulously overseeing every stage to guarantee consistency and precision. Furthermore, ACO Mold takes packaging seriously, employing comprehensive protective measures including soft filling materials and sturdy cardboard for lighter items, and pallets for heavier shipments. This attention to detail at every step, from material selection to the final packaging, underscores ACO Mold’s commitment to delivering excellence and reliability to its clients worldwide.

Pioneering Precision: ACO Mold’s Detailed Feasibility Analysis

ACO Mold revolutionizes mold manufacturing with its early-stage detailed feasibility analysis, ensuring the seamless success of molded parts. This thorough Design for Manufacturability (DFM) assessment focuses on critical factors:

- Assembly Analysis: Guarantees no interference in assembly, avoiding later modifications.

- Part Structure Analysis: Achieves functional requirements efficiently, minimizing costs.

- Parting Line and Mold Layout Analysis: Simplifies mold design for straightforward processing.

- Injection Gate Location and Method Analysis: Promotes efficient production and superior product aesthetics.

- Draft Angle and Wall Thickness Analysis: Ensures smooth ejection and identifies potential defects early on.

This proactive approach significantly reduces development time, prevents costly late-stage modifications, lowers production expenses, and enhances overall product quality. ACO Mold’s commitment to detailed preparatory work ensures a smooth transition from design to mass production, setting a new standard in manufacturing excellence.

Comprehensive After-Sales Support

Offering a seamless blend of flexibility and swift communication, this after-sales support service ensures that clients receive quotes within a rapid 24-hour timeframe, complemented by expert consultations. Tailored to meet the high standards of precision and client satisfaction, the service includes up to three complimentary mold trials. These trials serve as a critical step for clients to verify mold adequacy, ensuring every detail aligns with their stringent requirements before proceeding to full-scale production. In the exceptional circumstance where development falls short of expectations, clients are reassured with a full refund policy, reflecting the firm’s unwavering commitment to quality and trust. Beyond initial production, the service extends to include free replacements of wear parts throughout the product’s lifetime, marking a commitment to long-term reliability and customer care. This comprehensive after-sales support not only distinguishes the company within the mold manufacturing sector but also underscores its dedication to upholding exceptional standards of quality and client service.

About ACO Mold

ACO Mold, a distinguished plastic injection mold and molding manufacturer from China, has built a reputation of reliability among professional molders and makers across Europe and North America. With a history steeped in decades of collaboration with high-standard clientele, ACO Mold has developed a profound understanding of the intricacies of mold making, mastering international standards such as HASCO and DME for overseas exports. Through continuous investment in technology, equipment, and human resources, alongside processing optimization, ACO Mold has broadened its capabilities, aiming to deliver superior value to its customers. The company’s mission centers on becoming the most reputable and customer-focused Chinese injection mold supplier, emphasizing service-centricity and production efficiency enhancements. ACO Mold is committed to offering cost-effective solutions while fostering a productive work environment for enduring employee relationships, enhancing supplier ties, and nurturing trustful, beneficial partnerships with its clientele.

For more information, please visit https://www.acomold.com/ or contact +86 150-1247-2161 / sales@acomold.com

Media Contact:

ACO Mold

Phone: +86 150-1247-2161

Email: sales@acomold.com

Website: https://www.acomold.com/

Media Contact

Company Name: ACO Mold

Email: Send Email

Phone: +86 150-1247-2161

Address:65#, Dayang Industrial Zone, Songgang Street, Baoan District

City: Shenzhen, 518105

Country: China

Website: www.acomold.com