What is Hemostatic Sponge Made From?

Hemostatic sponges or you can also call them surgical sponges, because of their high use in surgeries to prevent bleeding. Likewise, they are also known as absorbable hemostatic gelatin sponges because they are made from absorbable ingredients like cellulose, bone gelatin, and other polymeric components. However, these components work best for the body’s coagulation process to stop bleeding.

A sponge is used in neurosurgery, dentistry, otolaryngology, gynecology, and surgeries to stop patient bleeding and burn the wound surface. Meanwhile, A hemostatic sponge encourages tissue regeneration and has absorbent and antimicrobial properties.

This post will explain what hemostatic sponges are made of and their significant applications in medical procedures.

Composition of Hemostatic Sponge

The composition of Hemostatic Sponges is essential for stopping the blood and making blood clots in the wounds. Its components are as follows:

Primary Material:

• Pharmaceutical Gelatin:

Most hemostatic sponges contain Pharmaceutical gelatin, a base protein derived from bovine bone. This bovine bone gelatin has various benefits.

• Absorbability:

When its surface absorbs the blood, it can form clots, preventing blood loss.

• Biodegradability:

This phenomenon means that when the human body naturally breaks down the gelatin, it helps form blood clots, which stops the bleeding.

• Thrombin:

Thrombin is an enzyme that directly empowers the clots to produce blood clotting.

• Fibrinogen:

The protein fibrinogen plays a crucial role in forming a blood clot.

Hemostatic Filling Materials

Hemostatic filling materials are divided into three types depending on their composition and function: polysaccharide-based materials, protein-based hemostatic reagents, and chemically generated compounds.

1. Chemically Generated Hemostatic Compounds:

Hemostasis chemicals are small monomers or polymers that can react chemically to generate gels and tissue binders. Although these materials have a far lower risk of viral infection than protein-based products, some difficulties, and many challenges arising from chemical toxicity and non-degradability persist.2.

2.Hemostatic Agents: Protein-Based

Protein-based hemostatic reagents, composed of thrombin, collagen, or fibrinogen, are identical to the EC/PGRF method in terms of high cost. They can infect, but they have a short life span. Protein-based hemostatic agents are indispensable in preventing bleeding in surgery. These agents function by employing proteins, like fibrin or collagen, that speed up the normal clotting process in the body.

When these proteins are used to cover the wound, they create a solid clot that stops bleeding and enhances recovery. Quick and efficient blood loss control is essential in surgical and acute care settings, providing significant value for protein-based hemostatic agents. They are biocompatible and usually work well with the body’s chemistry. Therefore, for healthcare practitioners, it has become an effective option to increase recovery times and improve patient outcomes.

3.Polymeric Hemostatic Materials Derived from Polysaccharide

They are primarily constructed of cellulose, chitosan, sodium alginate, and starch. Whatever way you look at it… they can create pretty much any sort of hemostatic product under the sun. This type of polymer gives you good biocompatibility, biodegradability, and non-immunogenic features.

What is Bovine Bone Gelatin?

Bovine bone gelatin is a very effective type of gelatin in all kinds of sponges. It is derived from cow bones or other cattle bones and has many benefits.

Meanwhile, this Bovine bone gelatin perfectly absorbs blood, forming many localized clots that effectively stop bleeding. The gelatin degrades gradually within the body, reducing the need for removal following use.

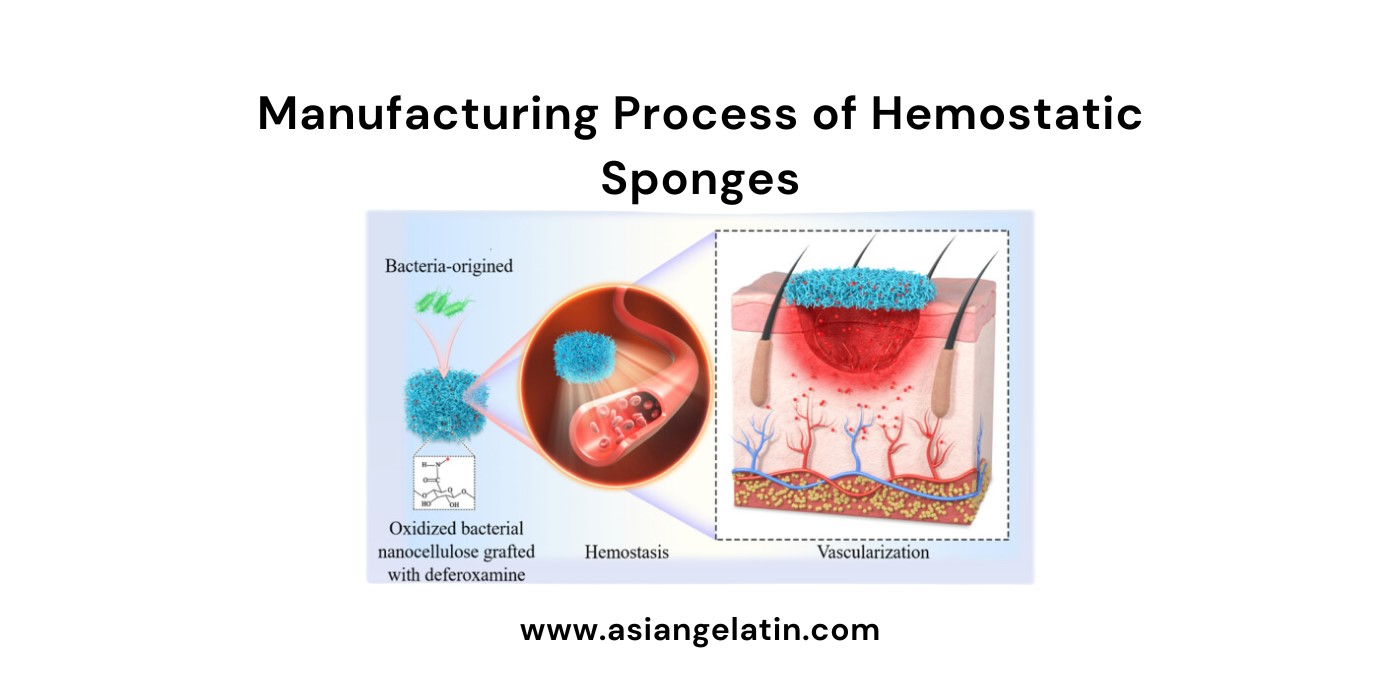

Manufacturing Process of Hemostatic Sponges

Hemostatic sponges are essential in surgery and wound care, but their design and composition significantly impact their effectiveness. Here, we look at a few ways to prepare these blood-clotting instruments:

1. Freeze-Drying:

This extensively used approach involves freezing the solution after a hemostatic substance, often gelatin, has been dissolved in a solvent. Next, a vacuum is supplied to the frozen mixture, causing the solvent to sublimate—a direct transition from solid to gas—without melting the ice. This destroys the ice crystals, leaving a porous sponge structure. When applied to a wound, the remaining gelatin matrix retains the hemostatic substance and promotes the formation of a blood clot.

2. Solvent Casting & Particulate Leaching:

Firstly, a solvent dissolves bone gelatin and other materials like fibrinogen and thrombin to start the process. After this, fluid comes out, which you can put in various molds and leave for some time to solidify. Once it is set, salts or sugar dissolve with a different solvent. After this leaching process, you get a porous material called hemostatic sponges, the best way to prevent bleeding.

3. Electrospinning:

This modern method uses an electric field to transform a polymer solution into fragile fibers. Meanwhile, the polymer solution is hemostatic sponges made from bone gelatin or other polymers. When you put this fiber-like material on a collector after it has an electric field, it forms a mat-shaped material. That’s how it forms a hemostatic sponge, which you can use for surgical purposes.

4. Lyophilization with Crosslinking:

This method uses crosslinking agents in conjunction with freeze-drying. Crosslinking regulates the sponge’s internal disintegration rate and strengthens its structure. Gelatin and a crosslinking agent are dissolved in a solvent and then freeze-dried. A chemical reaction forms crosslinks between the gelatin molecules in the resulting frozen matrix, strengthening the hemostatic sponge and allowing for controlled release.

Meanwhile, researchers continuously discover new methods to create hemostatic sponges for medical processes. Although sponges’ structures can be updated to give them more uses, such as antimicrobial properties, this research aims to use them as an alternative to plant-based polymers. However, the primary goal is to make more hemostatic sponges that are safer, useful, and updated.

Extraction and Processing of Bone Gelatin

The process of extraction of bone gelatin involves some steps such as:

- Bovine bones are purchased from trusted merchants and undergo a rigorous screening process to ensure their purity.

- Chemicals or enzymes are employed to extract collagen, the primary protein component of bone.

- The extracted collagen is subjected to a rigorous purification process that removes contaminants to achieve the properties required for pharmaceutical-grade gelatin.

- The final gelatin is sterilized to eliminate bacteria and viruses.

Benefits of Hemostatic Sponge

The hemostatic sponges are designed to prevent heavy blood loss in operating rooms and increase the power of creating clots so that the human body can heal itself faster and healthier.

• Promotes Faster Clotting and Wound Healing

The hemostatic sponges have many benefits, such as stopping the bleeding from wounds, absorbing blood, and starting to create clots. These chemicals upgrade the human body’s natural healing power and save the patient from heavy blood loss in case of any surgery.

• Helps Control Bleeding During Surgical Procedures

Hemostatic sponges are commonly used to control bleeding during various surgical procedures. They can be applied directly to the bleeding site to stimulate clot formation and provide mechanical support. This reduces the chance of difficulties and improves overall surgical efficiency by keeping the operational field free.

• Minimizes Blood Loss and Reduces the Risk of Complications

The hemostatic sponges stop blood loss and the risk of complications by perfecting the control over people’s bleeding wounds. Because heavy blood loss can cause patients to go into a coma or pass away, this lifesaver is always essential for all kinds of surgeries.

Applications of Hemostatic Sponges in Medicine

Hemostatic sponges have various applications in medicine for controlling bleeding:

o Use in Surgery for Controlling Bleeding

They are efficiently being used in many surgical procedures to prevent blood loss. Traditional methods, such as ligatures or pressure, do not work well, so doctors use hemostatic sponges. You can quickly put them on a bleeding spot, and they start to stimulate the clot formation and give mechanical support.

o Advantages Over Other Products

Comparing hemostatic sponges to other goods, the following are some benefits of using ingredients like chitosan and gelatin:

• Faster hemostasis with high absorbency and rapid blood absorption.

• Safe and biocompatible with low risk of adverse reactions.

• Promotes tissue regeneration and effective wound healing.

o Use in Orthopedic Surgeries

Furthermore, they are used in orthopedic surgeries as well. During surgery, they work best to prevent blood loss. Meanwhile, the absorbable hemostatic gelatin sponge aims to absorb all the moisture or blood with its porous structure to reduce bleeding.

o Use in Dental Procedures

The next application of hemostatic sponges can also be used in dental surgeries such as tooth extractions, periodontal operations, and other oral surgical interventions. Their ability to control the bleeding is fantastic in this complex surgery.

o Effectiveness in Various Surgeries

Ultimately, this absorbable hemostatic gelatin sponge works effectively for different surgery needs. However, its ability to stop a person’s bleeding is essential in medical science because of its use; it is honestly a lifesaver. The main surgery uses include gynecology, neurology, otolaryngology, and general surgery.

Conclusion

So, this was the article about what hemostatic sponges are made from. Hopefully, you will find all the answers you were searching for. Meanwhile, It provides different benefits in various fields of medical science like surgery, and its power is to stop excessive bleeding by absorbing moisture.

Researchers are still looking for new possibilities for its future use in the medicine industry and for saving more lives.

Media Contact

Company Name: xiamen Yasin Industry and Trade Co., Ltd.

Email: Send Email

Country: China

Website: https://www.asiangelatin.com/